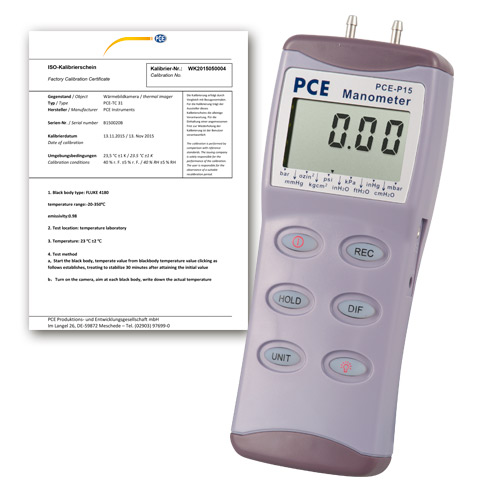

Differential Pressure Manometer PCE-P15-ICA Incl. ISO Calibration Certificate

PCE-P15-ICA

Availability : กรุณาติดต่อสอบถาม

Here you can see a professional differential pressure manometer with the highest accuracy and best performance. With this differential manometer you can not only measure. The pressure readings can easily be transferred online to a PC or laptop. The differential pressure gauge is ideal for use in industry, in service and in the laboratory. The device is particularly suitable for measuring non-corrosive media. The overload protection is twice the measuring range. The 9 units that can be shown on the display make this differential manometer universally applicable for the practitioner on site and saves laborious conversion of the measurement results (conversion table of the pressure units).

If you want to transfer the measurement data from the differential manometer to the computer, you need the optional software and the RS-232 interface cable. The software runs in conjunction with the Windows® versions `95,` 98, `2000 and ME / XP (short info: pressure measuring device with interface). The principle of absolute and differential pressure measurement is explained if you follow the link below: Principle of absolute and differential pressure measurement. DIN ISO 9000 calibration certificates for the pressure gauges and corresponding accessories are also available.

Software

The software for data transfer and the interface cable can optionally be ordered as a package. The differential manometer is connected to the PC with the RS-232 cable. The software is installed from the CD. The pictures below give you an optical impression of the software. The differential manometer transmits the respective measured values online to the PC.

The values determined on the differential manometer are plotted directly on the y-axis. The differential pressure values are indicated with “-” in a field below the graphic (visible on the top left picture (in the red circle)). The measuring units can be changed to the desired unit both on the differential manometer and in the software. All measured values are written in a data file and can be saved under any name on the hard disk of the computer. Many customers also transfer the values to e.g. MS Excel for further analysis.

– 9 selectable units

– Digital display of over, under (vacuum) or differential pressure

– Min / Max memory

– Data hold function

– Backlit LCD display

– Impact-resistant ABS housing

– Auto-power-off function

– Incl. ISO calibration certificate

Further areas of application

The applications of the differential manometer are diverse.

For example, it is used in:

– Pneumatic area, on compressors and pumping systems

– Chemical area for process control, measurements on pressure tanks

– Manufacturing area, for compressed air press processes e.g. in the plastics industry

– Checking valve controls (before- after- loss of compressed air)

– Research and development area

– In general for optimization and testing in the process

– Authorization area for heating and air conditioning systems

| Pressure Meter | Parameter | PCE-P15 | |

| Max. Pressure | positive/ negative or overpressure / vacuum | 30 psi | |

| PSI | Range | 0…±15 | |

| Resolution | 0.01 | ||

| mbar | Range | 0…±1000 | |

| Resolution | 1 | ||

| inH20 | Range | 0…±415 | |

| Resolution | 0.3 | ||

| inHg | Range | 0…±30.5 | |

| Resolution | 0.005 | ||

| mmHg | Range | 0…±750 | |

| Resolution | 0.5 | ||

| kPa | Range | 0…±100 | |

| Resolution | 0.1 | ||

| cmH20 | Range | 0…±1050 | |

| Resolution | 1 | ||

| Kg/cm² | Range | 0…±1.05 | |

| Resolution | 0.001 | ||

| Data format | Baud rate: 2400 baud,1 stop bit, 8 data bits | ||

| Accuracy | ±0.3 % (full range, @ +25°C / +77°F) | ||

| Repeatability | ±0.2 % (max. ±0.5 % of full scale) | ||

| Duration | 0.3 ms | ||

| Operating temperature max | +50 °C / +122 °F | ||

| Battery | 1 x 9 V – block battery PP3 | ||

| Dimensions | 182 x 72 x 30 mm / 7.1 x 2.8 x 1.1″ | ||

| Weight | 150 g / 5.3 oz | ||

เฉพาะลูกค้าที่เข้าสู่ระบบ และเคยซื้อสินค้าชิ้นนี้แล้วเท่านั้น ที่เขียนบทวิจารณ์ได้

สินค้าที่เกี่ยวข้อง

Manometer

PCE-PDA 1000L

Manometer

PCE-DPG 25

Manometer

PCE-DMM 50

PCE-DPG 10-ICA

Manometer

PCE-DMM 11

Manometer

PCE-DMM 20

Manometer

PCE-PDA 1L

Manometer

PCE-PDA A100L

รีวิว

ยังไม่มีบทวิจารณ์