Accelerometer Data Logger PCE-VDL 24I 3-Axis

PCE-VDL 24I

Availability : กรุณาติดต่อสอบถาม

3-Axis Accelerometer Data Logger with 1600Hz Sampling Rate

This 3-axis data logger is supplied with the acceleration sensor with a sampling rate of 1600 Hz. The sensor measures the acceleration currently acting on it (3 axes), like upon shock or during vibration. The measurements take place in predetermined (selectable) time intervals. The measured data recorded with the internally installed 3-axis accelerometer are stored in the datalogger on a 4 GB memory card. Thus, the data logger is ideally suited to determine the acceleration during: fault diagnosis / stress test of components (improve the quality of your products), machine inspection, shock measurements and, in general, in the preventive maintenance. Use the data logger for acceleration as a cost-effective tool for avoiding machine breakdown and downtime. – It is very difficult to make up for the once lost production time -.

Small and self-sufficient

The compact design allows the user to mount or set up the data logger for 3-axis acceleration almost anywhere – just the smallest measuring surfaces must be available. The supplied software makes the setup as well as the evaluation of the measured and recorded data from the acceleration sensor possible. When ordering, the customer always receives the latest version of the software. The latter is also available for download in the “download area” of PCE Instruments. Even if there is no power supply, the measurement data of the acceleration remain available in the data logger so that the user did not lose any data.

Accurate reconstruction of accelerations and shock pulses in all three axes

Due to the triaxial acceleration sensor installed into the data logger, a wide range of applications in the field of acceleration measurement with a very high sampling rate of 1600 Hz appears. From the one side, it is possible to apply the 3-axis accelerometer on stationary objects such as machines, motors or generators in order to record operating conditions at different process steps. Does a motor when driving up or down operate within certain speed ranges by resonances and cause strong accelerations with heavy loads on machine structures and the environment? The corresponding areas can be limited with the triaxial acceleration sensor, with an additional information in which of the three spatial axes the largest oscillation amplitudes occur. This information can be used, for example, in the design of the damping systems. In addition to stationary objects, the 3-axis acceleration data logger can also be installed on the moving objects. Thus, not only shocks, impacts or general accelerations of the objects in all 3 axes can be determined; due to the constant presence of the gravitational acceleration and its graphical and numerical display in the measurement results, also small changes in position, shifts and general tilting in three-dimensional space thanks to the higher sampling rate can be recorded at the highest resolution. The 3-axis acceleration logger is therefore suitable for a large number of applications in the industrial or transportation sector.

In order to represent accelerations in all 3-axes in the best possible way and with the higher resolution over the course of time, it is necessary to have as many measurement values as possible with an exact time stamp. Only in this way it is possible subsequently to precisely visualize and analyse the event progression corresponding to the real processes by means of an acceleration-time-diagram. The 3-axis accelerometer from PCE Instruments makes exactly this task possible. Due to the high sampling rate of 1600 Hz, the 3-axis accelerometer is particularly suitable for recording of the high-frequency oscillations or vibration and of very short shock or impact pulses. If, for example, periodic oscillations with higher frequency components are to be recorded and subsequently displayed via the PC software, a sufficiently high sampling rate is necessary in order to reconstruct the oscillations accurately and without distortions. The same applies to shock loads. Extremely short load peaks can also be visualized only then if very many measurement points are recorded in very short time intervals. This is possible with the 3-axis accelerometer from PCE Instruments. At 1600 Hz sampling rate, the data logger can display time intervals in the magnitude of 0.4 milliseconds and thus make very short mechanical impact loads visible. With the aid of a Damage Boundary Curve (DBC), these impact loads can be qualitatively classified in all 3-axes in order to predict or reliably detect possible damage to machinery, products, equipment or freight transport.

| 3-Axis Acceleration Measured Variable | |

| Measuring range | ±16 g |

| Accuracy | ±0.24 g |

| Measurement / storage rate | 1600 Hz … 1 Hz |

| General Technical Data of the 3-Axis Accelerometer | |

| Storage capacity | 2.5 million measured values per measurement, 3.2 billion measured values with the enclosed 32 GB microSD memory card |

| Button | Start / stop of a measurement; On or off switch of the data logger |

| LED | Log: operating status |

| Power supply | Integrated Li-Ion battery 3.7 V / 500 mAh |

| Integrated sensors | 3-axis acceleration |

| Interface | USB |

| PC Software | Free setup and evaluation software (Windows XP / Vista / 7/8/10 32-bit / 64-bit) for recording and evaluating the data. |

| Operating conditions | Temperature -20 … +65 °C |

| Storage conditions | Temperature +5 … +45 °C (ideal |

| Standards | The PCE-VDL 24I complies with the EU RoHS / WEEE directive. |

| Weight | ca. 60 g |

| Dimensions (L x W x H) | 87 x 44 x 23 mm |

สินค้าที่เกี่ยวข้อง

Data Logger / Data Logging Instrument

PCE-USM

Data Logger / Data Logging Instrument

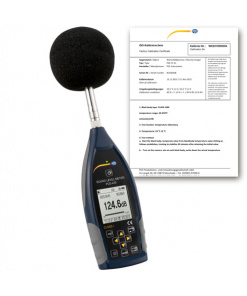

Calibrator Data Logger PCE-MCA 50-ICA incl. ISO Calibration Certificate

PCE-MCA 50-ICA

Data Logger / Data Logging Instrument

Sound Level Data Logger w/GPS PCE-432-ICA incl. ISO Cal. Cert.

PCE-432-ICA

Data Logger / Data Logging Instrument

PCE-HT 72

Data Logger / Data Logging Instrument

Noise Data Logger PCE-322ALEQ-ICA incl. ISO Calibration Certificate

PCE-322ALEQ-ICA

Data Logger / Data Logging Instrument

Sound Level Data Logger PCE-430-ICA incl. ISO Calibration Certificate

PCE-430-ICA

Data Logger / Data Logging Instrument

PCE-PHD 1-PH

Data Logger / Data Logging Instrument

pH / Cond. / Salt / Oxygen Water Quality Data Logger PCE-PHD 1-ICA incl. ISO Cal

PCE-PHD 1-ICA