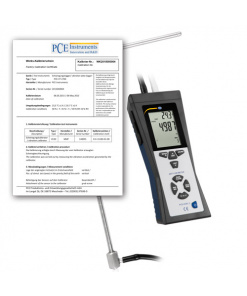

Hot Wire Anemometer PCE-423

PCE-423

Availability : กรุณาติดต่อสอบถาม

High-resolution Hot Wire Anemometer for Measuring Air Velocity and Temperature

various units selectable / hot wire telescopic probe extendable up to 1 meter / USB data cable and software for online data transmission

The PCE-423 is a Hot Wire Anemometer for measuring temperature, volume flow and flow velocity. The Hot Wire Anemometer, consisting of a display unit and a heat wire probe, enables a fast and precise measurement, especially of the low air speeds. The measuring range of the high-resolution anemometer ranges from the smallest flow velocities up to 25 m / s. There, different units (m / s, knots, km / h, mph, ft / min) can be selected for the flow velocity. For volume flow measurements, a distinction can be made between CFM and CMM.

Due to the combination of a telescopic rod and a thin measuring head, a Hot Wire Anemometer from PCE can be used in the places, where there is little measuring space available or where the measuring point is difficult to reach for the examiner. The telescopic probe of the Hot Wire Anemometer can be extended to a length of up to one meter and its measuring head has a diameter of ten millimetres.

The user of the device is able to read out the results optimally even in a dark environment. It is possible, because the large, illuminated LC display on the Hot Wire Anemometer facilitates the measurement of the air flow in low light conditions. A Hot Wire Anemometer, like the PCE-423, stores maximum and minimum values that can be retrieved on the display later. So that the last measurement results could be viewed again, the Hot Wire Anemometer has a Data-Hold function. In order to save the battery when the device is not in use, the Hot Wire Anemometer has an integrated Auto-Power-Off function, which ensures that the meter shuts off by itself after five minutes.

After entering the channel cross-section, a Hot Wire Anemometer, besides measuring the temperature and flow velocity, also allows for the determination of the volume flow in channels.

To log the measured values, the flowmeter is equipped with a USB interface. As a result, with the help of the supplied software, the data can be transferred to a PC and evaluated.

Hot Wire Anemometer Buying Guide

Devices for the measurement of wind and flow velocities are also called anemometers. They are divided into hot wire anemometers, vane anemometers and Pitot tube anemometers according to their operating principle. Hot wire anemometers and hot film anemometers use the relationship between flow velocity and heat emission; that is why they are also referred to as thermal anemometers. Even being small children, we can already see that the heat is released to the cooler surroundings faster, for example, when we blow on hot food. In the hot wire anemometer, a thin wire or conductive film is electrically heated – the hot wire or hot film. The more heat-dissipating air flows around the heated sensor component, the faster it cools down. The electrical resistance decreases for the wire as well as for the hot film with dropping temperature. These are PTC resistors (PTC for positive temperature coefficient). Due to their mode of operation, many hot wire anemometers are well suited for very low wind speeds, since they have the highest sensitivity in the lower measuring range. Hot wire anemometers can also be designed for high speeds, even for supersonic applications. When the heating capacity is minimal, a hot wire anemometer can also be used as a very fast-reacting thermometer.

Areas of application for hot wire anemometers

Due to the sensitive reaction, hot wire anemometers are well suited for the detection of low currents. That is why they are often used for measurements in homes and workplaces to localize the unwanted air flows. Due to the compact sensor shape of the hot wire anemometer, they can be used to check the flow conditions in the narrow shafts or pipes and to find leaks. The effectiveness of the ventilation systems or suction devices in the clinics, open-plan offices, meeting places or at the production facilities can also be checked with a hot wire anemometer. Hot wire anemometers are used in the production of diesel engines and components of ventilation systems to check the values of the air intake or exhaust devices. In agriculture and for disinfection, it is advisable to check the flow conditions with a hot wire anemometer before applying powders or spray mist. If the flow is too strong, the material may be unintentionally distributed to the other places.

Sensor structure of the hot wire anemometer

For the hot wire anemometers, thermistors or wires made of platinum, nickel, tungsten or other metals are usually used, which are only 2.5 to 10 μm thick and at least 200 times as long. The flow rate is mainly measured perpendicular to the thermistor or hot wire. In the case of hot wires, the diameter plays a decisive role in determination of the detectable frequencies. The reaction speed increases as the wire diameter decreases.

Since the hot wires and hot film elements are also mechanically very sensitive, they are often protected from accidental damage by special protective caps. Depending on the design of the thermal resistance and the protective caps, it must be ensured that the sensor is dependent on the flow direction. In the case of direction-dependent sensors, there are often special arrows on the sensor, which indicate the direction of flow. In order for the hot wire anemometer to correctly record the flow velocity, the sensor must be rotated so that the direction of the arrow and the flow matched.

For accurate measurements, the hot wire must be free of contaminants. Dust or other deposits affect the heat emitted to the environment and thus the measurement result. The sensor rod is often designed as a telescopic rod. This enables the hot wire anemometers to register and measure the flows even in the hard-to-reach places. Inside the rod, the connecting cables from the thermal resistance to the electronic components in the device are routed.

Measuring principles of the hot wire anemometers

Two methods are used to determine the flow-related heat loss in the hot wire anemometer and based on that, the flow velocity. Either the measurement at the constant current (CCA – Constant Current Anemometry) or the measurement at the constant temperature (CTA – Constant Temperature Anemometry) are used.

Hot wire anemometers with constant current anemometry (CCA) work with constant heating current. If the temperature changes on the hot wire, the resistance changes and a change in voltage can be measured. If the hot wire cools down further due to the high flow velocity, the measured voltage becomes lower. However, the sensitivity decreases with the increasing flow speed. Such CCA hot wire anemometers are simple and well suited for low speeds.

Hot wire anemometers with constant temperature anemometry (CTA) keep the temperature of the hot wire constant. To keep this temperature constantly above the ambient temperature, the ambient temperature is measured. If the hot wire is cooled by air flow, the hot wire anemometer increases the heating current to reach the target temperature again. At higher flow speeds, the hot wire is cooled down faster and more heating current has to be used. The consumed heating current is measured and from this, the flow rate is determined. The temperature dependence of convection is compensated by the CTA hot wire anemometer through the evaluation of the ambient temperature. Since the flow rate also depends on the air pressure, some of the CTA hot wire anemometers have an additional sensor to measure the air pressure. This makes the CTA hot wire anemometers technically more complex than CCA hot wire anemometers; however they can work over a larger measuring range and compensate for temperature influences and, with appropriate equipment, also for the influence of the air pressure.

Direction measurement with the hot wire anemometer

For the measurements during which the direction of the flow is also to be determined, the sensors with several thermal resistances are necessary. The resistors are arranged so that the hot wire anemometer can determine the direction of the flow from a different heat emission. The direction of the flow can be recorded in two or three dimensions, depending on the number and arrangement of the hot wires or hot film elements. Weather vanes on the rooftops that indicate the wind direction are two-dimensional. For the three-dimensional measurement, the plane perpendicular to the cardinal direction is also taken into account.

The hot wire anemometers, the probe of which has three appropriately arranged hot wires, can also register flow angles and turbulence. This also makes the high-resolution measurements for jet drives or during the processes with unsteady flows possible.

– Suitable for low velocity air flow

– multiple measurement units available

– Large LCD display

– Data-Hold function

– Easy-to-use

– Shows max. y min. values on the display

– Solid enclosure

– Auto shut-off to protect battery life

– Comes with telescopic hot wire / thermal probe (max. length: 1 m / 3.3 ft), software, USB data cable batteries, carrying case and user’s manual

| Measurement ranges | |

| 0.1 m/s … 25.0 m/s | |

| 20 ft/min … 4925 ft/min | |

| 0.2 kn … 48.5 kn | |

| 0.3 km/h … 90.0 km/h | |

| 0.2 mph … 55.8 mph | |

| 0.0°C … 50.0°C / 32°F … 122°F | |

| Resolution | |

| 0.01 m/s | |

| 1 ft/min | |

| 0.1 kn | |

| 0.1 km/h | |

| 0.1 mph | |

| 0.1°C / 32.2°F | |

| Accuracy | |

| Air velocity | ± 5% ± 1 digit (of the measurement field) |

| Temperature | ± 1°C / 33.8°F |

| Thermal probe | Telescopic thermal probe |

| Length unextended | 185 mm / 7.3 in |

| Length extended | 1000 mm / 39.4 in |

| Maximum diameter | 12 mm / 0.5 in |

| Minimum diameter | 10 mm / 0.4 in |

| Measurement quota | Approx. 0.8 s |

| Display | LCD display 46.7 mm x 60 mm / 1.8 in x 2.4 in |

| Interface | USB |

| Operating conditions | 0°C … 50°C / 32°F … 122°F 80% H.r. |

| Power | 9V battery |

| Auto shut-off | After 5 min. of inactivity |

| Dimensions | 210 mm x 75 mm x 50 mm / 8.3 in x 3.0 in x 2.0 in |

| Enclosure | ABS plastic |

| Weight | 280 g / < 1 lb |

สินค้าที่เกี่ยวข้อง

เครื่องวัดความเร็วลม Anemometer

Vane Anemometer PCE-VA 11-ICA incl. ISO Calibration Certificate

Volumetric Flow Rate Anemometer PCE-VA 11-ICA incl. ISO [...]

เครื่องวัดความเร็วลม Anemometer

PCE-WSAC 50-810

เครื่องวัดความเร็วลม Anemometer

Pitot Tube Anemometer PCE-HVAC 2-ICA incl. ISO Calibration Certificate

PCE-HVAC 2-ICA

เครื่องวัดความเร็วลม Anemometer

Anemometer PCE-WSAC 50W 230-ICA incl ISO calibration certificate

PCE-WSAC 50W 230-ICA

เครื่องวัดความเร็วลม Anemometer

PCE-VA 20

เครื่องวัดความเร็วลม Anemometer

PCE-VA 20-SET

เครื่องวัดความเร็วลม Anemometer

PCE-WSAC 50-910

เครื่องวัดความเร็วลม Anemometer

PCE-A420